Assuring quality products and documentation is a top priority at Midwest Precision. We have extensive investments in equipment and highly experienced personnel who are very knowledgeable with the requirements of our core markets in Aerospace, Defense, Energy and Fluid Power.

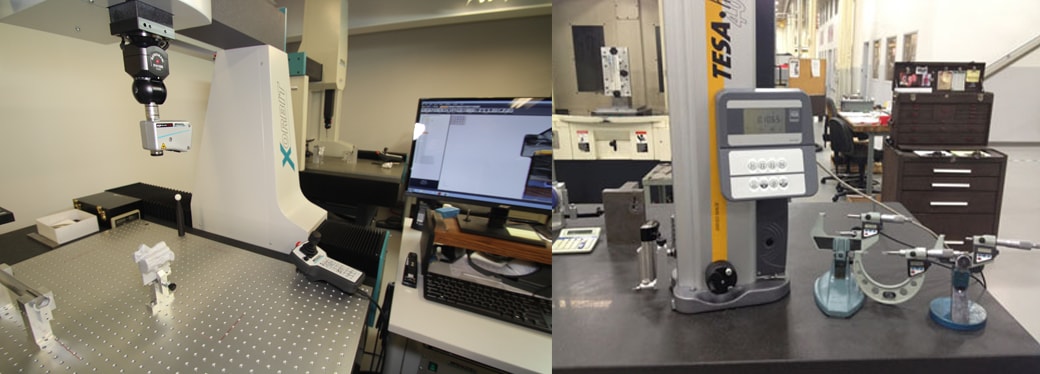

Our Quality Assurance Lab is climate-controlled with state of the art equipment. The QA team works closely with Engineering and Manufacturing to insure quality products with minimal waste.

Midwest Precision's Quality System is certified to AS9100D with ISO 9001:2015 standards. Extensive record keeping maintains full traceability from raw material through finished products. Midwest Precision is registered for ITAR compliance.

Building quality into the parts at the point of manufacture and preventing defects is our number-one priority. We incorporate rigorous in-process inspection methods utilizing statistical techniques to monitor process performance and make adjustments proactively.

Midwest Precision utilizes electronic gaging throughout the shop floor for improved accuracy and to support electronic record keeping by customer job number/part number. This process eliminates error and improves productivity of inspection personnel.

View AS9100D with ISO 9001:2015 Certificate Registration

Midwest Precision Quality Assurance

- QA lab, climate-controlled with state of the art equipment.

- Certified to AS9100D with ISO 9001:2015 standards

- Full traceability from raw material through finished products

- Registered for ITAR compliance

- (2) Programmable Wenzel CMM’s with Renishaw heads

- Surfcom 480A surface analyzer

- TESA Height Stand

- SPC data analysis

- Optical Comparators

- Full compliment of standard measurement equipment